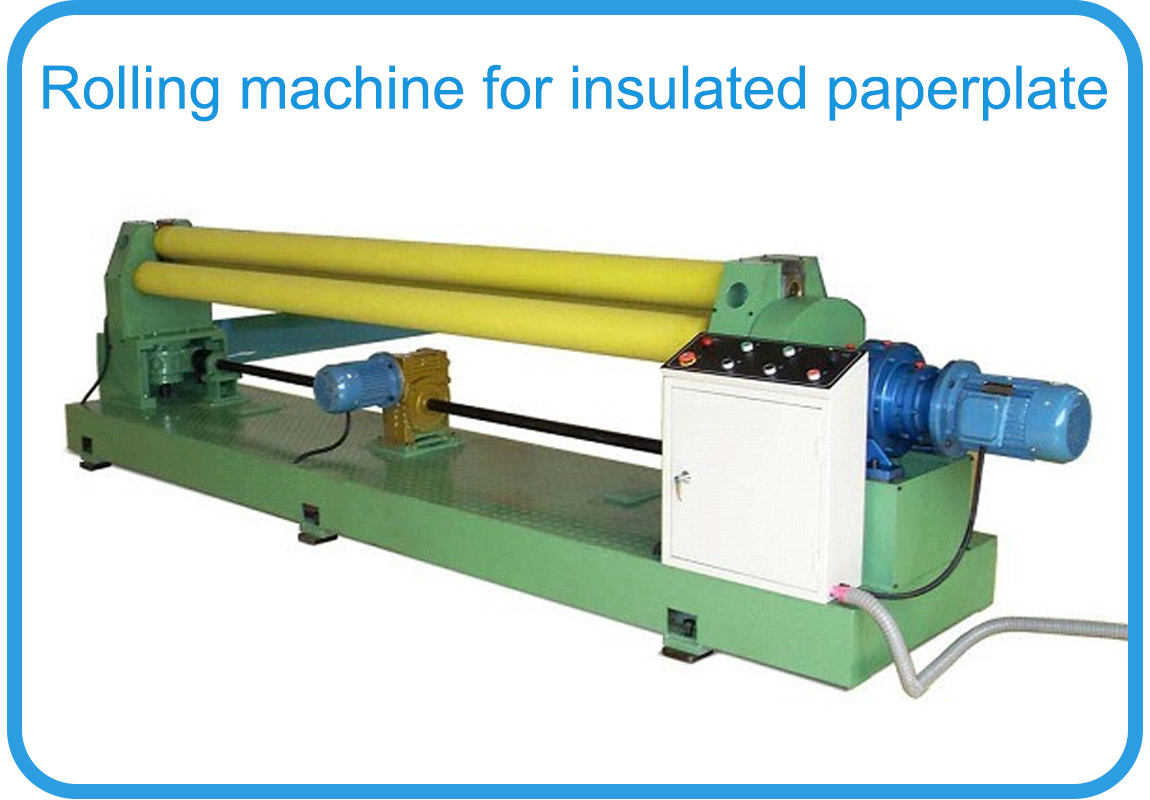

ROLLING MACHINE FOR INSULATED PAPERPLATE

Category:

INSULATION PROCESSING EQUIPMENT

Product Display

Product Features

The equipment mainly consists of upper and lower rollers, supports, bases, transmission systems, electrical systems, etc.

1. After the insulation cardboard roll is formed, it will not damage the surface, and is safe to operate. It is designed reasonably, sturdy and durable, and suitable for mass production of transformer insulation cardboard rolls.

2. After processing, the surface of the insulated paper cylinder has no deformation or burrs.

3. The surface of the insulated paper cylinder after processing is free of oil stains and rust.

4. The outer layer of the roll is treated with polyurethane glue or electroplating.

Technical Parameters

|

parameter

|

GY-13 type Rolling machine |

GY-16type Rolling machine |

GY-20type Rolling machine |

|

Thickness of the insulation board |

1-5mm |

1-6mm |

1-6mm |

|

Max width |

1300 mm |

1600 mm |

2000 mm |

|

Rolling speed |

3m/min |

3m/min |

3m/min |

|

Min diameter of paper tube |

200mm |

250mm |

280mm |

|

Power |

2.2KW |

3KW |

4KW |

|

Overall dimension |

2500x700x1000mm |

2800x700x1000mm |

3200x1000x1000mm |

Support customization according to customer requirements.

Our Factory

Why Choose Us?

1

We have our own factory.

2

Products can be customized

3

High quality product and good price.

4

Good Pre-sale、on sale and after sales service.

5

Short delivery time.

6

Exported all over the world, with rich experience.

Honor

RELATED PRODUCTS

MESSAGE