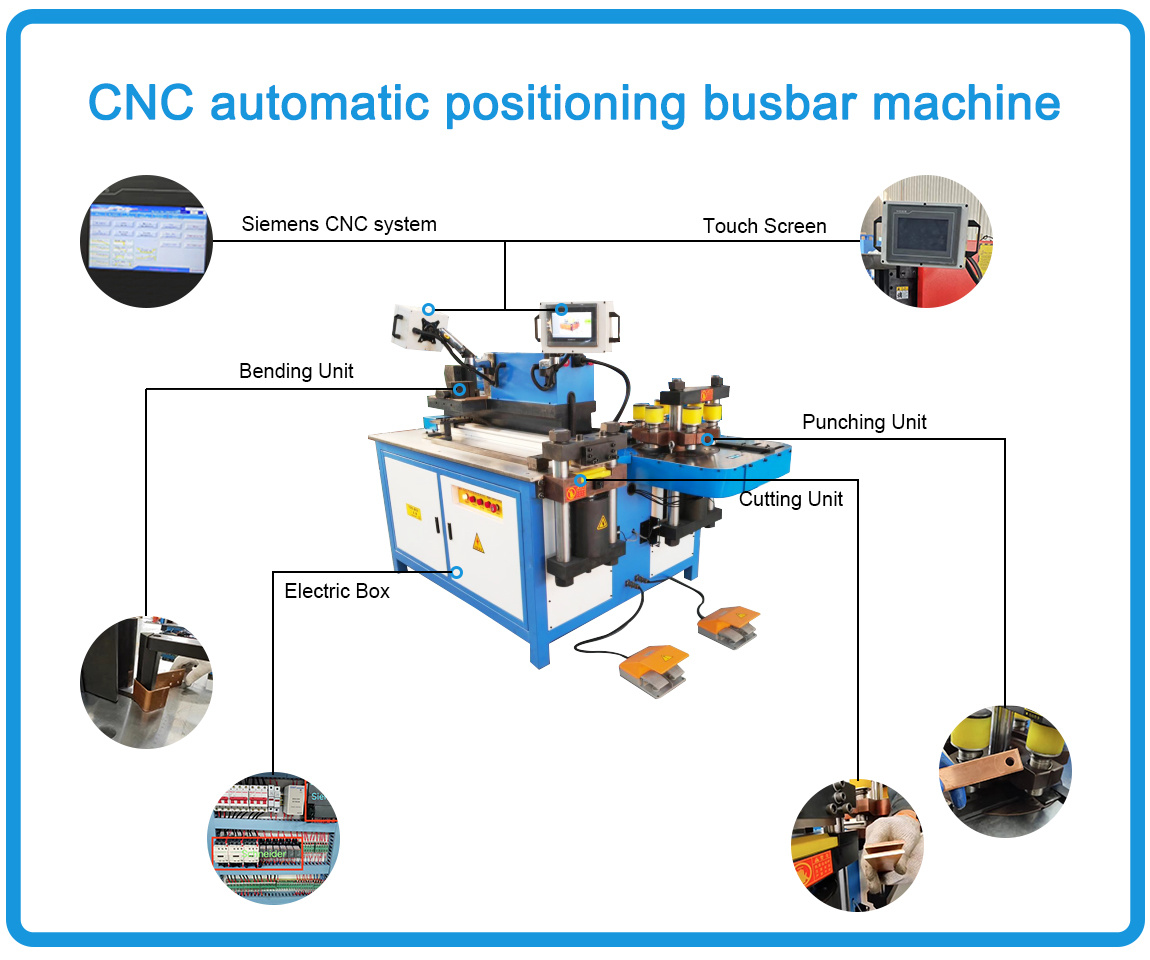

AUTO POSITION BUSBAR MACHINE

Category:

BUSBAR PROCESSING MACHINE

Product Display

Product Features

Automatic Positioning Function

|

|

|

Cutting:The size to be cut can be set through the touch screen for automatic positioning。 |

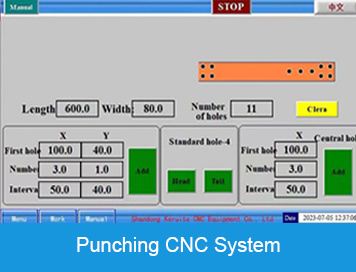

Punching:Set required punching distance and pitch on the touch screen, and the Y-axis and X-axis positions can be automatically adjusted to achieve high-precision punching without the need for marking. |

|

|

|

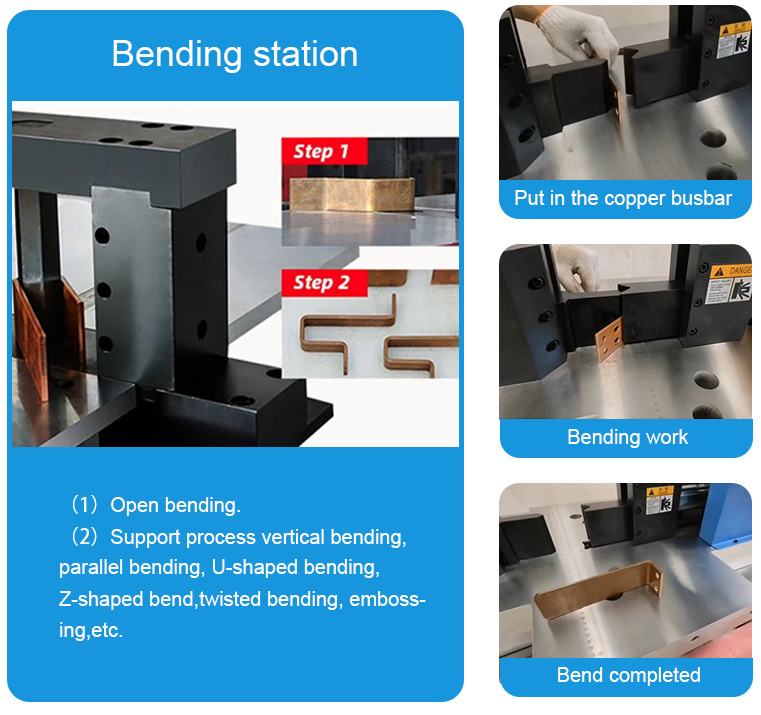

Bending:Set the bent distance and angle through the touch screen, and the X-axis automatically adjusts the positioning Y-axis for CNC hydraulic control of the bending angle, achieving high-precision bending without the need for scribing. |

|

Product Details

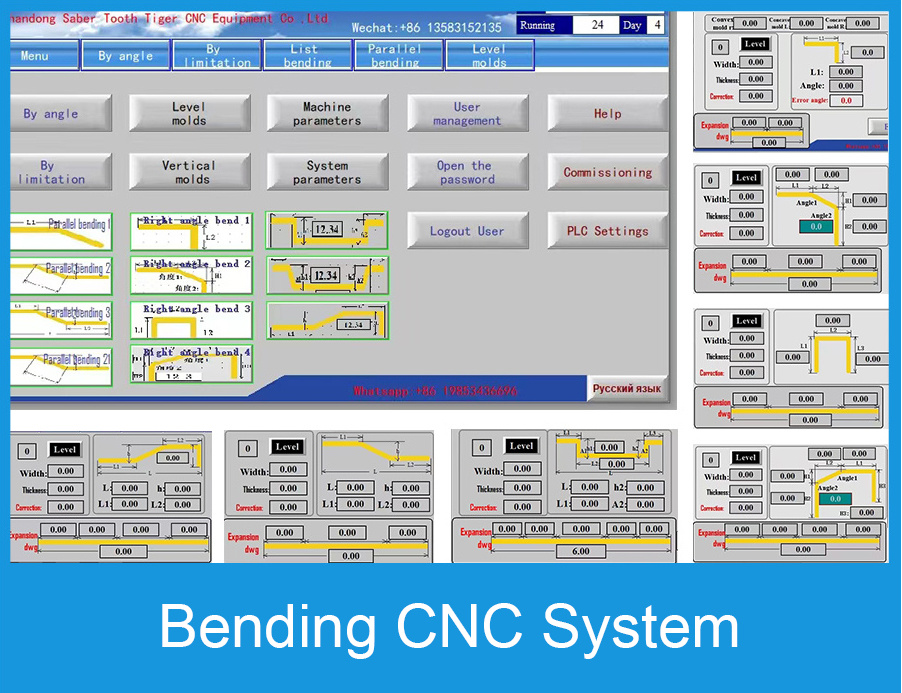

Bending CNC system can calculate various bending angles and unfolding lengths of copper busbar to save materials for users.Store multiple sets of parameters for next use without the need for repeated editing.

|

|

|

Equipped with coordinate drawing function, it can more intuitively display the actual coordinate effect, |

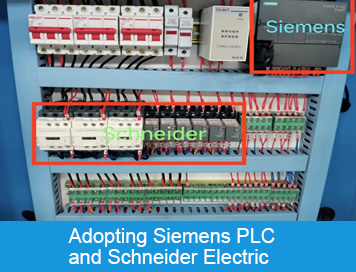

Adopt Siemens PLC and Schneider Electric to ensure the safety and stability of the machine, avoiding machine fault and making it more durable. |

|

|

|

Equipped with automatic refueling function.Adopt three power motors are used, corresponding to the punching, shearing, and folding stations, to ensure stable power for the three stations, each performing its own duties without interfering with each other. |

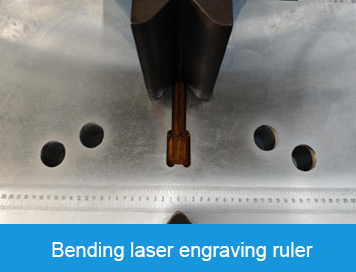

The graduation ruler of the bending station adopts laser engraving, which will not cause damage to the bottom of the copper busbar due to friction when working. |

Technical Parameters

|

Function |

Item |

ZTMX-303-4K |

ZTMX-303-3K |

ZTMX-503-4K |

ZTMX-503-3K |

|

Punching

|

Max power(KN) |

350 |

350 |

550 |

550 |

|

Punching Diameter(mm) |

φ4.3-φ32 |

φ4.3-φ32 |

φ4.3-φ32 |

φ4.3-φ32 |

|

|

Max size(mm) |

160x12 |

160x12 |

260x16 |

260x16 |

|

|

Automatic positioning range

|

Y-axis: 0-1000mm |

Y-axis: 0-1000mm |

Y-axis: 0-1000mm |

Y-axis: 0-1000mm |

|

|

X-axis: 0-120mm |

X-axis: 0-120mm |

X-axis: 0-220mm |

X-axis: 0-220mm |

||

|

Shearing/cutting

|

Max thickness(mm) |

12 |

12 |

16 |

16 |

|

Max width(mm) |

160 |

160 |

260 |

260 |

|

|

Max power(KN) |

350 |

350 |

550 |

550 |

|

|

Positioning range(mm) |

Y-axis:0-1000mm (Auto positioning) |

0-1000mm (manual positioning) |

Y-axis:0-1000mm (Auto positioning) |

0-1000mm (manual positioning) |

|

|

Bending

|

Max power(KN) |

350 |

350 |

550 |

550 |

|

Max width(mm) |

160 |

160 |

260 |

260 |

|

|

Max vertical bending thickness (mm) |

12 |

12 |

16 |

16 |

|

|

Max Automatic positioning stroke(mm) |

450mm |

450mm |

450mm |

450mm |

|

|

Max horizontal bending size(mm) |

110x10mm |

110x10mm |

110x10mm |

110x10mm |

|

|

Automatic positioning accuracy |

mm |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

|

Power of Motor |

(KW) |

14 |

14 |

14 |

14 |

|

Weight of machine |

(T) |

1.6 |

1.6 |

2.1 |

1.6 |

|

Outline Dimensions |

(mm) |

2100*1600*1500 |

2100*1600*1400 |

2100*1600*1500 |

2100*1600*1400 |

All automatic positioning lengths can be customized according to user requirements.

Sample Display

Accessory Checklist:

|

No. |

Item |

Quantity |

|

|

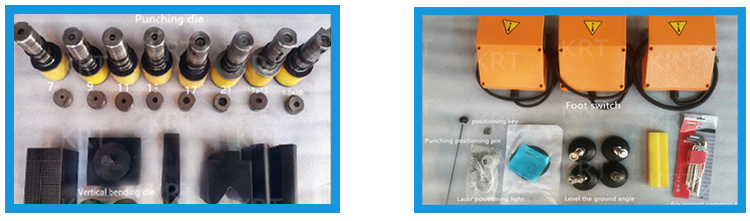

1

|

Punching mold

|

8 sets

|

Round hole:7/9/11/13/17/21 |

|

Oval hole:11×15/13×18 |

|||

|

2 |

Vertical bending mold |

2 sets |

(R5/R10) |

|

3 |

Horizontal bending mold |

1 set |

|

|

4 |

Small bending mold |

1 set(R3) |

|

|

5 |

Die pins |

2 pieces |

|

|

6 |

Equipment manual |

1 set |

|

|

7 |

Foot switch |

3 pairs |

|

|

8 |

U-bending mold |

1 piece |

|

|

9 |

Spare proximity switch |

1 piece |

|

|

10 |

Equipment common tool |

1 set |

|

|

11 |

Punching laser positioning light |

1 piece |

|

|

12 |

Punching positioning needle |

1 piece |

|

|

13 |

Embossing mold |

1 set |

|

|

14 |

Spare sealing ring |

1 piece |

|

|

15 |

Level the ground angle |

4 pieces |

|

|

16 |

Cutting blade |

1 pc (Installed on machine) |

|

Packaging and Shipping

Our Factory

Why Choose Us?

1

We have our own factory.

2

Products can be customized

3

High quality product and good price.

4

Good Pre-sale、on sale and after sales service.

5

Short delivery time.

6

Exported all over the world, with rich experience.

Honor

RELATED PRODUCTS

MESSAGE