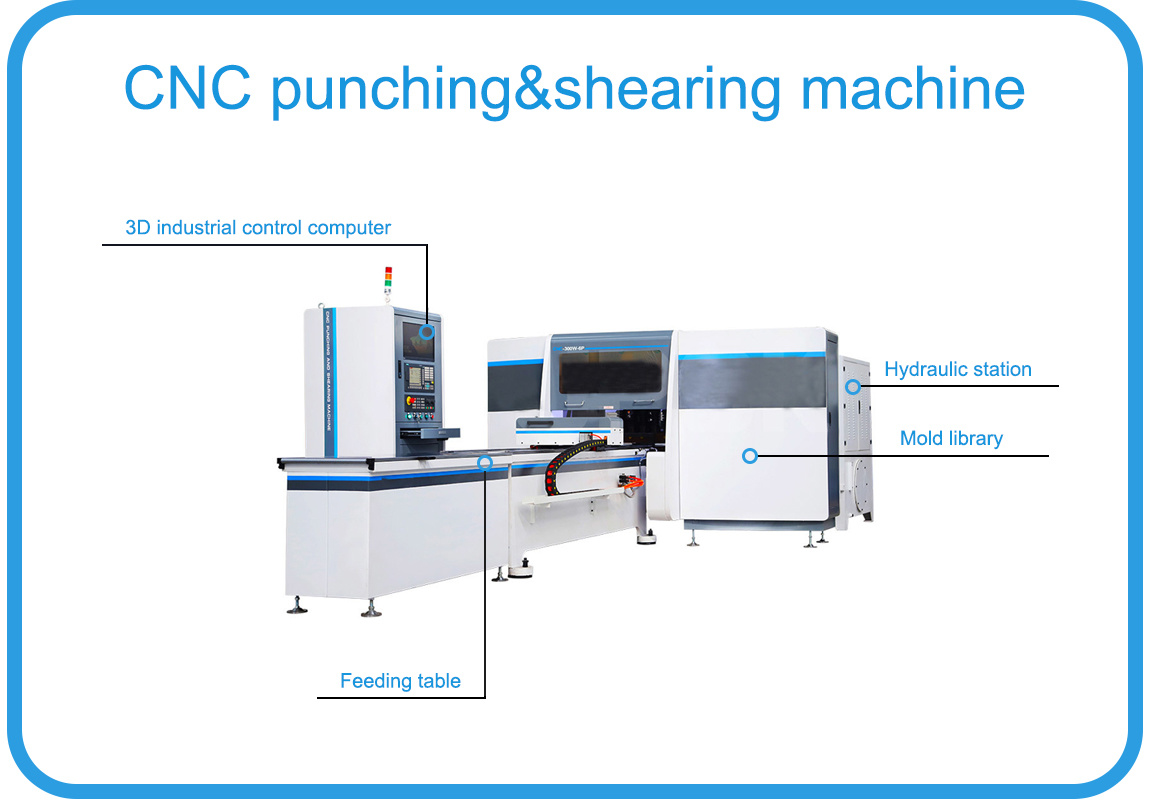

CNC PUNCHING&SHEARING MACHINE

Category:

BUSBAR PROCESSING MACHINE

Product Display

Product Description

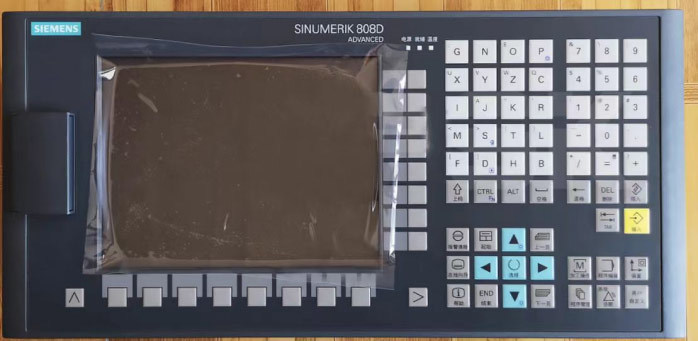

Siemens(808D)CNC System.

|

|

| Operators can directly perform CAD 2D drawing or SOLIDWORKS 3D drawing on the equipment, directly generating programs for processing.. You can also directly import drawings for processing. | |

|

|

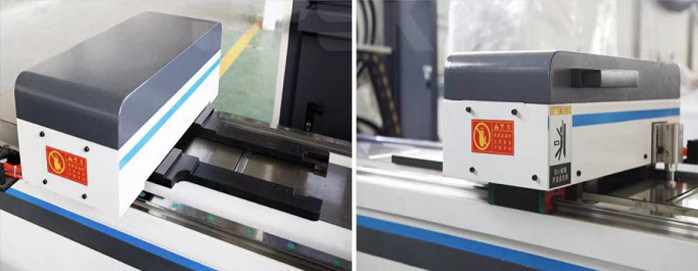

| Adopt double clamps to work together, which can effectively reduce the machining accuracy error caused by not level busbars in single-sided clamps. | |

|

|

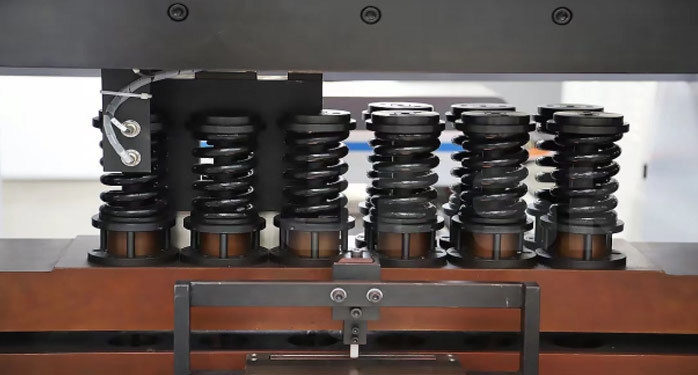

| The mold library is a nine punch one shear mold library that can meet different processing requirements for copper and aluminum busbars, such as cutting, punching circular holes, punching long circular holes, punching square holes, chamfering, and other process requirements. | |

|

|

| Use a new hydraulic system. Lower energy consumption, lower noise, better reliability, and is equipped with air-cooled radiators for good heat dissipation. | |

|

|

| The frame of this machine is welded and processed with high-quality medium thick steel plates, ensuring that the accuracy and stability of the frame are maintained during long-term use. |

Product Parameters

|

Parameter |

Unit |

KMX-802CJ-6P |

|

|

Nominal force

|

Cutting |

KN |

500 |

|

Embossing |

KN |

500 |

|

|

Punching |

KN |

500 |

|

|

Wide range |

mm |

15-200 |

|

|

Thickness range |

mm |

3-15mm |

|

|

Punching range |

mm |

Φ4.3-Φ35mm |

|

|

Max positioning speed of X1 (feeding axis), X2 axis (workpiece drag axis) |

m/min |

65 |

|

|

Max stroke of X1-axis (discharge) |

mm |

2000 |

|

|

Max stroke of X1-axis (feed) |

mm |

300 |

|

|

Max effective stroke of Y-axis |

mm |

530 |

|

|

Max stroke of Z-axis |

mm |

350 |

|

|

Strike cylinder stroke |

mm |

50 |

|

|

Strike frequency |

HPM |

150 |

|

|

Workpiece operation strike frequency |

HPM |

100 |

|

|

Mold number

|

Punching mold |

Set |

9 |

|

Cutting mold |

Set |

1 |

|

|

Embossing mold |

Set |

1 |

|

|

Number of servo control axes |

|

6 |

|

|

Hole spacing control accuracy |

mm/m |

±0.20 |

|

|

Max allowable diameter for once punching |

mm |

Φ36 |

|

|

Max allowable plate (Lx W x T) |

mm |

6000×200×14 |

|

|

Main machine weight |

kg |

6100 |

|

|

Machine footprint |

mm |

10500×2800x1780 |

|

|

Max hydraulic force |

Mpa |

31.5 |

|

|

Total motor power |

KW |

22.5 |

|

Support customization according to customer requirements.

Main Part

|

NO,. |

Name |

Description |

|

1 |

Imported original integrated CNC system |

Siemens(Including servo motor and servo driver) |

|

2 |

Sensor |

Siemens |

|

3 |

Control buttons |

Siemens |

|

4 |

AC contactor |

ABB |

|

5 |

Circuit breaker |

ABB |

|

6 |

Computer control software |

Support DXF/STEP format |

|

Drive system |

||

|

1 |

linear slider(45mm) |

Taiwan HIWIN |

|

2 |

Ball screw |

Taiwan HIWIN |

|

3 |

Screw support bearing |

Japan NSK |

|

Hydraulic part |

||

|

1 |

Pipe joint |

America PK |

|

2 |

High pressure oil pipe |

Parker Hannifin |

|

3 |

Sealing element |

America PK |

|

4 |

High and low pressure combination pump, hydraulic valve |

YUKEN |

|

5 |

Motor |

WNM |

|

6 |

Hydraulic station power |

11KW |

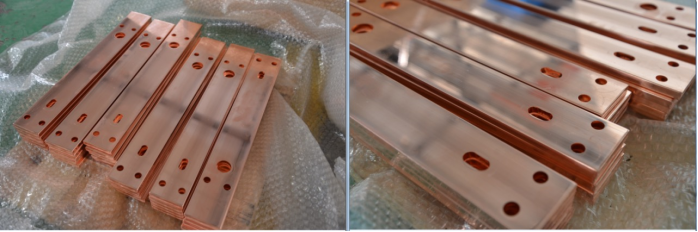

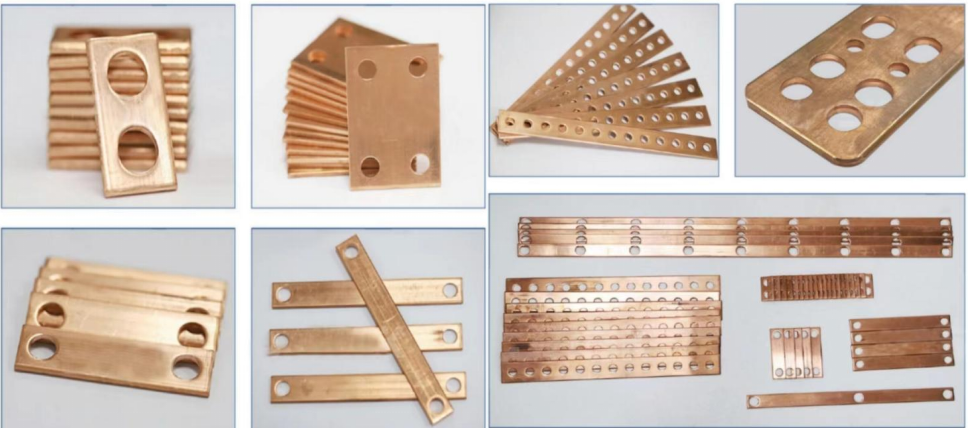

Sample Show

Configuration Checklist

|

Punching mold |

φ7、φ9、φ11、φ13、φ17、φ21/13x18/17x21(each 1 set) |

|

Cutting knife |

1 pc (Installed on the machine) |

|

Embossing mold |

1 set (Installed on the machine) |

Our Factory

Why Choose Us?

1

We have our own factory.

2

Products can be customized

3

High quality product and good price.

4

Good Pre-sale、on sale and after sales service.

5

Short delivery time.

6

Exported all over the world, with rich experience.

Honor

RELATED PRODUCTS

MESSAGE