CNC BUSBAR BENDING MACHINE

Category:

BUSBAR PROCESSING MACHINE

Product Display

Product Features

|

|

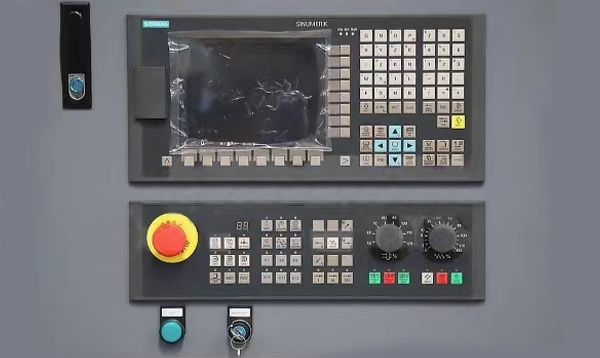

| By using 2-axis digital control, various specifications of bending work can be achieved on the busbar through one-time clamping. | The use of the 808D Siemens system control method has the advantages of simple operation, ease of use, fewer fault points, convenient maintenance, high efficiency, low consumption, precision and accuracy, and low-carbon environmental protection. |

|

|

| This machine adopts advanced principles such as AC servo CNC side blocking, grating control of machining angle, etc., to achieve a blocking positioning accuracy of ± 0.1mm. | |

|

|

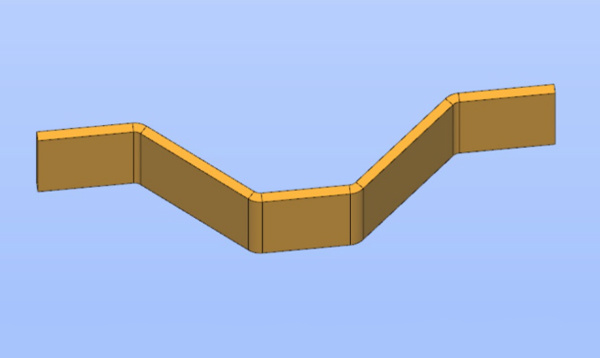

| During operation, simply import the drawings of the busbar to be processed into the equipment, and cooperate with industrial computer programming and related operations to complete the horizontal and vertical bending of the busbar. | |

|

|

| After the processing program is started, it can be processed directly, which improves efficiency, reduces labor intensity, generates no surplus or waste, and has no discharge of three wastes. It is safe, efficient, precise, and environmentally friendly. | |

Technical Parameters

|

Parameter |

Unit |

ZW-50SK |

|

Nominal force |

KN |

550 |

|

Max bending stroke |

mm |

220 |

|

Automatic side gear ruler stroke |

mm |

1600 |

|

Automatic side gear ruler positioning accuracy |

mm |

±0.1/m |

|

Max movement speed of side blocking material (X-axis) |

m/min |

0-15 |

|

Bending speed |

m/min |

0-5 |

|

Bending angle accuracy |

° |

±0.5° |

|

Max processing copper busbar size |

mm |

Width180×Thickness16 |

|

Total motor power |

KW |

6.5 |

|

Weight |

T |

2.3T |

|

Outline Dimensions |

mm |

3500x1800x2000 |

Support customization according to customer requirements.

Main Component

|

NO. |

Name |

Description |

|

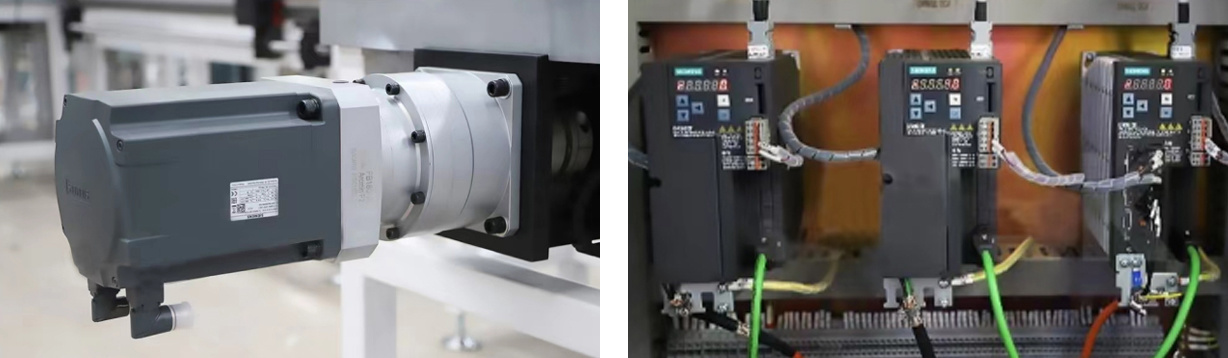

1 |

X、Y-axis CNC servo motor |

Siemens |

|

2 |

Servo-drive |

Siemens |

|

3 |

AC contactor, air switch |

ABB |

|

4 |

Miniature circuit breaker |

ABB |

|

5 |

CNC system |

Siemens(808D) |

|

6 |

Guide rails and screw rods |

Taiwan HIWIN |

|

7 |

Computer IPC |

Lenovo |

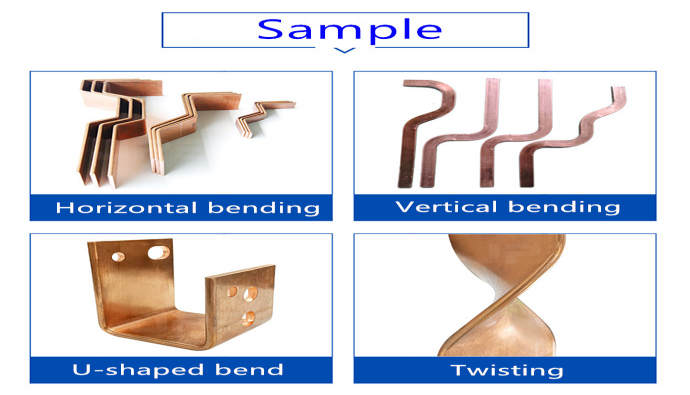

Sample Display

Configuration Checklist

|

No. |

Item |

Quantity |

|

1 |

U-shaped mold |

1 pc |

|

2 |

Horizontal bending mold |

2 sets(R5,R10) |

|

3 |

Maintenance tools |

1 set |

|

4 |

Foot pedal |

1 pair |

|

5 |

Vertical bending die |

1 set |

|

6 |

Equipment manual |

1pc |

Our Factory

Why Choose Us?

1

We have our own factory.

2

Products can be customized

3

High quality product and good price.

4

Good Pre-sale、on sale and after sales service.

5

Short delivery time.

6

Exported all over the world, with rich experience.

Honor

RELATED PRODUCTS

MESSAGE