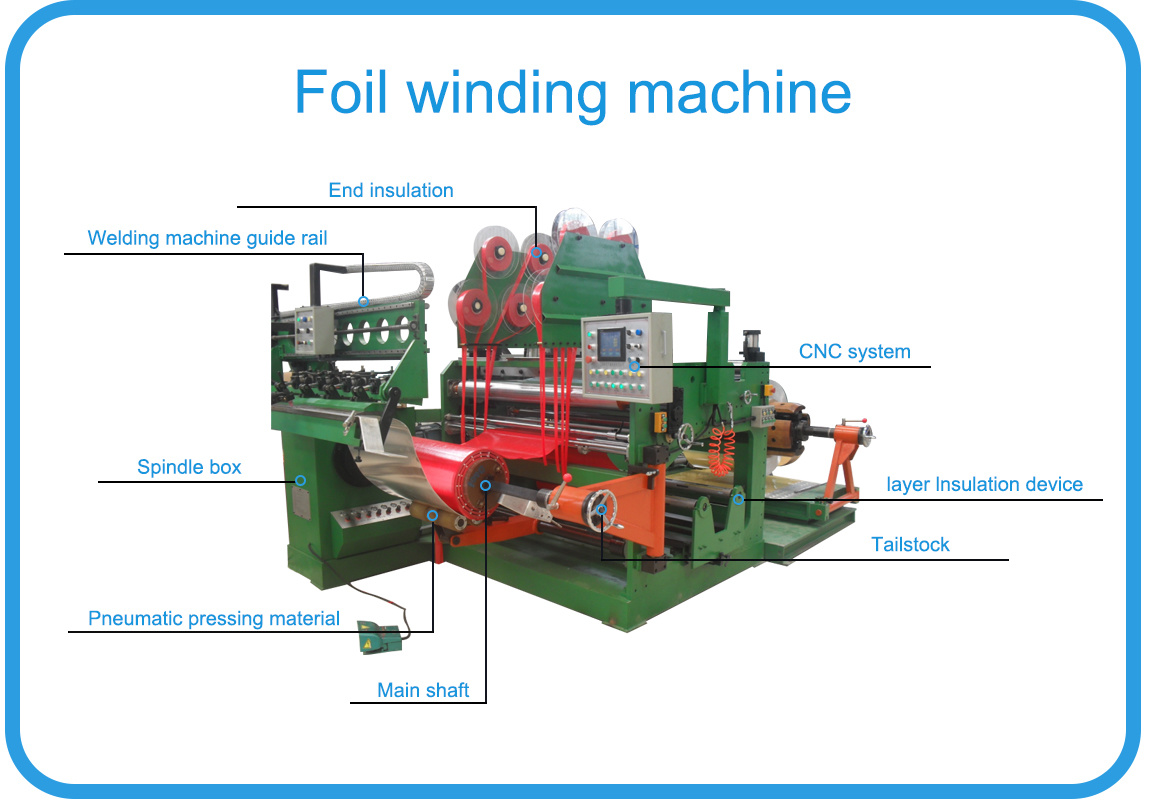

FOIL WINDING MACHINE

Category:

TRANSFORMER WINDING MACHINE

Product Display

1.This device is equipped with automatic guide wheel correction, which automatically adjusts the position of the foil, making it more convenient and reliable.

2.The host adopts advanced CNC screen control, with high automation level and simple and reliable operation.

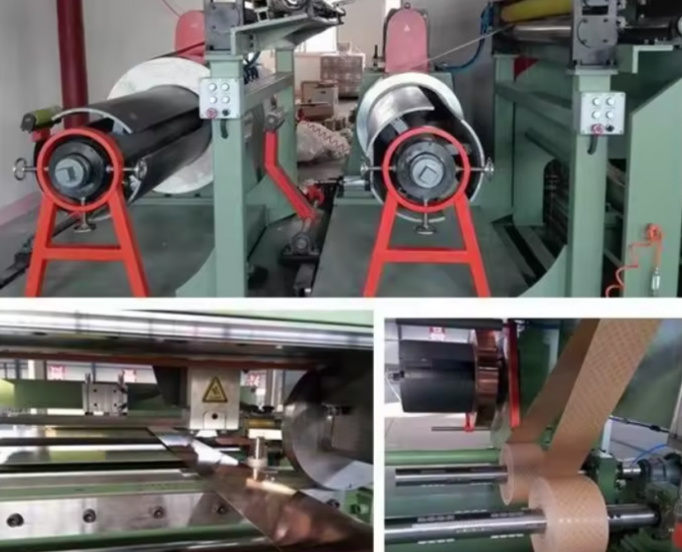

3.The foil unwinding device adopts motor control to achieve material receiving and discharging functions, making it easy to operate.

4.The tension of the foil material adopts advanced tension vector control technology, which has adjustable tension control accuracy and convenience.

5.The tension of interlayer paper is achieved by using an inflatable shaft for easy and fast loading and unloading of materials.

Technical Parameters

No. | Item | BRJ-1400 | BRJ-1100 | BRJ-800 | |||

1

|

Coil processing range

| 1.1 Shaft length | 500-1400mm | 250-1100mm | 180-800mm | ||

1.2 Shaft length(Including lead wire) | 650-1550mm | 400-1250mm | 330-950mm | ||||

1.3 Outer diameter (excluding row) | Diameter ₵700 | Diameter¢700 | Diameter¢700 | ||||

1.4 Max outer diameter | Diameter ₵800 | Diameter¢800 | Diameter¢800 | ||||

1.5 Min internal diameter | Diameter ₵130 | Diameter¢100 | Diameter¢100 | ||||

1.6 Coil | Round/ Rectangle | Round/Rectangle | Round/Rectangle | ||||

2

|

Coil material

| 2.1 Type of material | Copper foil/ Aluminum foil | Copper foil/ Aluminum foil | Copper foil/ Aluminum foil | ||

2.2 Width | 450-1250mm | 200-1050MM | 180-750MM | ||||

2.3 Thickness

| Copper | 0.5-2mm | 0.3-2mm | 0.3-2mm | |||

Aluminum | 0.5-3mm | 0.5-3mm | 0.5-3mm | ||||

3

|

Uncoiling machine

| 3.1 Internal diameter of material | Diameter ₵400/500 | Diameter 400/500 | Diameter 400/500 | ||

3.2 Outer diameter of material | Diameter ₵1000 | Diameter ₵1000 | Diameter ₵1000 | ||||

3.3 Effective length of charging barrel | 1400mm | 1150mm | 850mm | ||||

3.4 Expansion and contraction size of charging barrel | Diameter ₵400-520 | Diameter ₵400-520 | Diameter ₵400-520 | ||||

3.5 Load capacity of charging barrel | 2000kg | 2000kg | 1000kg | ||||

3.6 Tension force

| 10-18000N | 10-12000N | 10-10000N | ||||

20-30000N | 20-20000 |

| |||||

3.7 Tensioning working pressure | 0-0.6MP | 0-0.6MP | 0-0.6MP | ||||

4

|

Winding machine

| 4.1 Working torque | >12000N/M | >10000N/M | >8000N/M | ||

4.2 Winding power | Double layer, single layer 18.5KW | Double layer18.5KW, single layer 15KW | Double layer15KW, single layer 11KW | ||||

4.3 Speed adjustment mode | Variable frequency stepless speed regulation | Variable frequency stepless speed regulation | Variable frequency stepless speed regulation | ||||

4.4 Winding shaft | 50x90x1850mm | 50x90x1550mm | 50x90x1250mm | ||||

4.5 Winding speed | 0-20r/min | 0-25r/min | 0-30r/min | ||||

5 | 5.1 Welding method | TIG | TIG | TIG | |||

| 5.2 Welding speed | Auto 0-1m/min | Auto 0-1m/min | Auto 0-1m/min | |||

6 | 6.1 Shearing device | Screw rod disc cutter | Screw rod disc cutter | Screw rod disc cutter | |||

| 6.2 Searing speed | 1.5 m/min | 1.5 m/min | 1.5 m/min | |||

| 6.3 Shearing length | 1400MM | 1100MM | 800MM | |||

7 | 7.1 Layer insulation mounting shaft | 2 sets | 2 sets | 2 sets | |||

| 7.2 Shaft outer diameter | ₵400mm | ₵400mm | ₵400mm | |||

| 7.3 Internal diameter | 76mm | 76mm | 76mm | |||

| 7.4 Available shaft length | 1400 | 1100 | 800 | |||

8

|

End insulation device

| 8.1 Quantity | 10 sets (Support customization) | 10 sets (Support customization) | 4 sets (Support customization) | ||

8.2 Outer diameter | ₵350mm | ₵350mm | ₵350mm | ||||

8.3 Internal diameter | 56mm | 56mm | 56mm | ||||

8.4 Width | 15-50mm | 15-50mm | 15-50mm | ||||

9 | Electric control system | PLC automatic control mode | PLC automatic control mode | PLC automatic control mode | |||

10 | Counting accuracy | 0.1 turns | 0.1 turns | 0.1 turns | |||

11 | Deviation correction mode | servo system | servo system | servo system | |||

| Deviation correction accuracy | ±0.1mm | ±0.1mm | ±0.1mm | |||

12 | Overall dimensions of the machine(single-layer) | 4600mmX2850mm X2200mm | 4300mmX2600mm X2000mm | 3800mmX2300mm X1800mm | |||

13 | Overall dimensions of the machine (double layer) | 6200mmX2850mm X2500mm | 5500mmX2600mm X2250mm | 4800mmX2300mm X2050mm | |||

Support customization according to customer requirements.

Our Factory

Why Choose Us?

1

We have our own factory.

2

Products can be customized

3

High quality product and good price.

4

Good Pre-sale、on sale and after sales service.

5

Short delivery time.

6

Exported all over the world, with rich experience.

Honor

RELATED PRODUCTS

MESSAGE