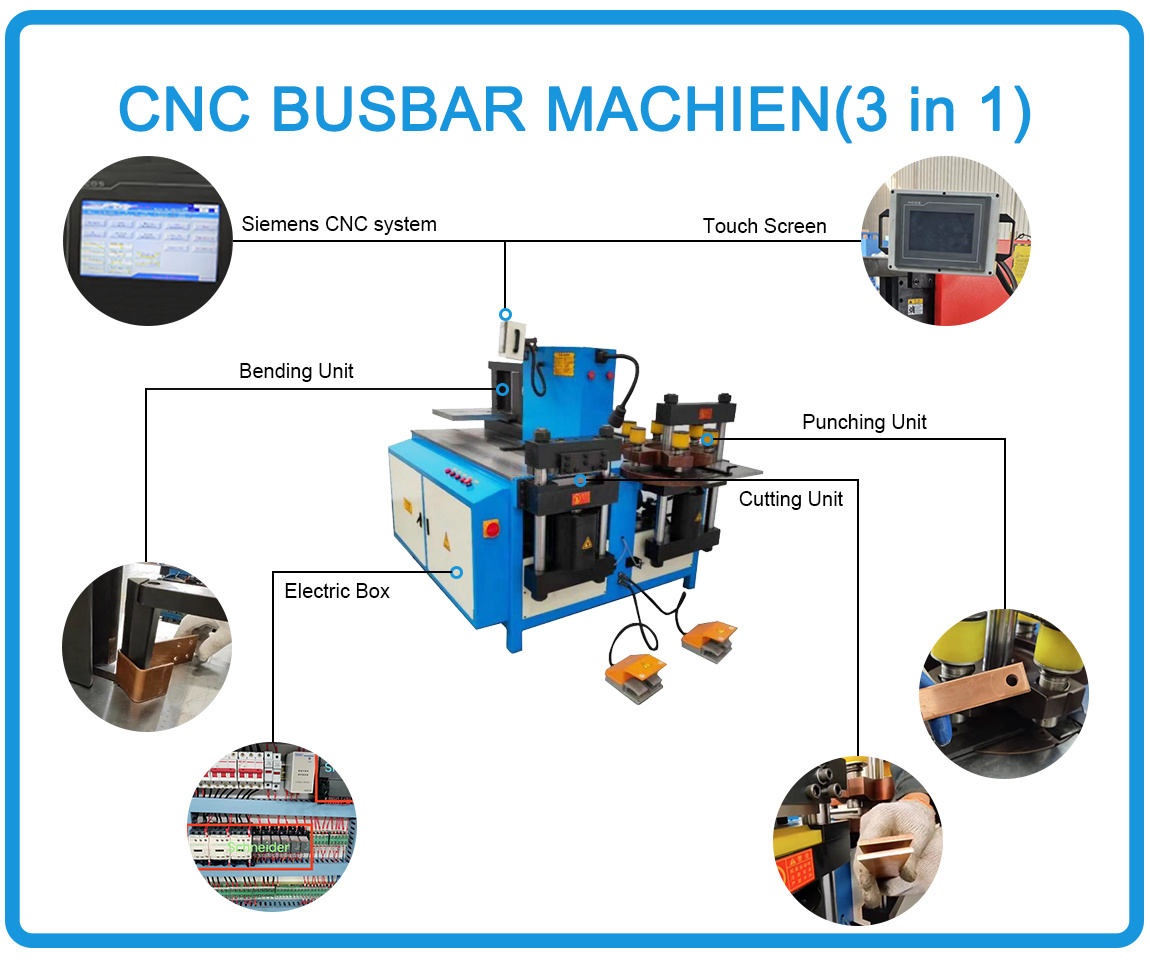

CNC BUSBAR MACHINE-ZTMX-30 SERIES

Category:

BUSBAR PROCESSING MACHINE

Product Display

Product Features

Product Details

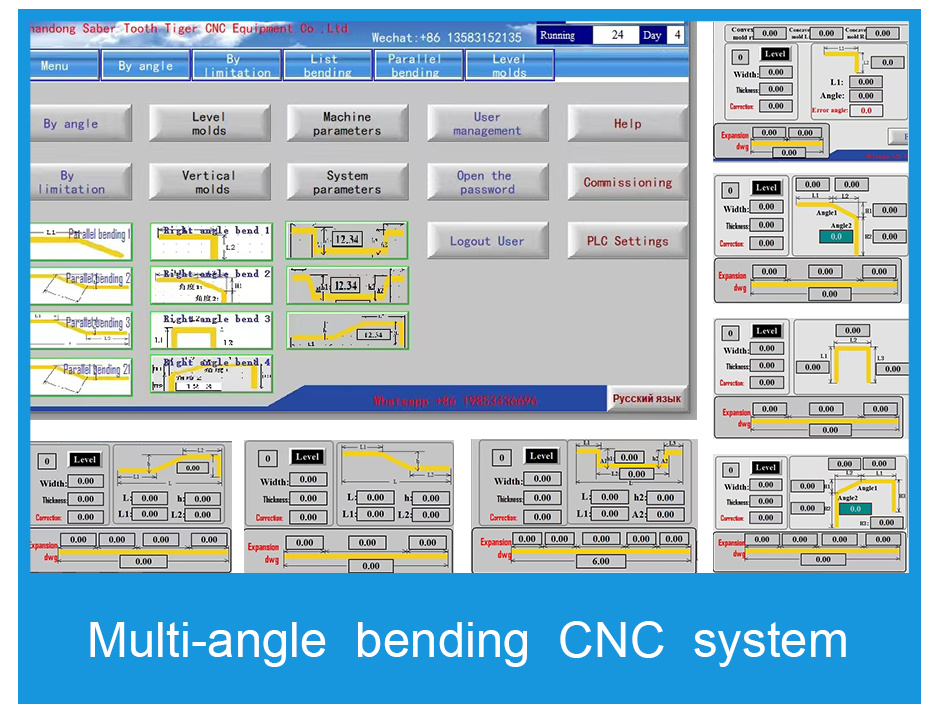

1.The CNC system adopts the highest configuration Siemens system, calculating various bending angles and unfolding lengths of copper busbar to save materials for users.Store multiple sets of parameters for next use without the need for repeated editing.

|  |

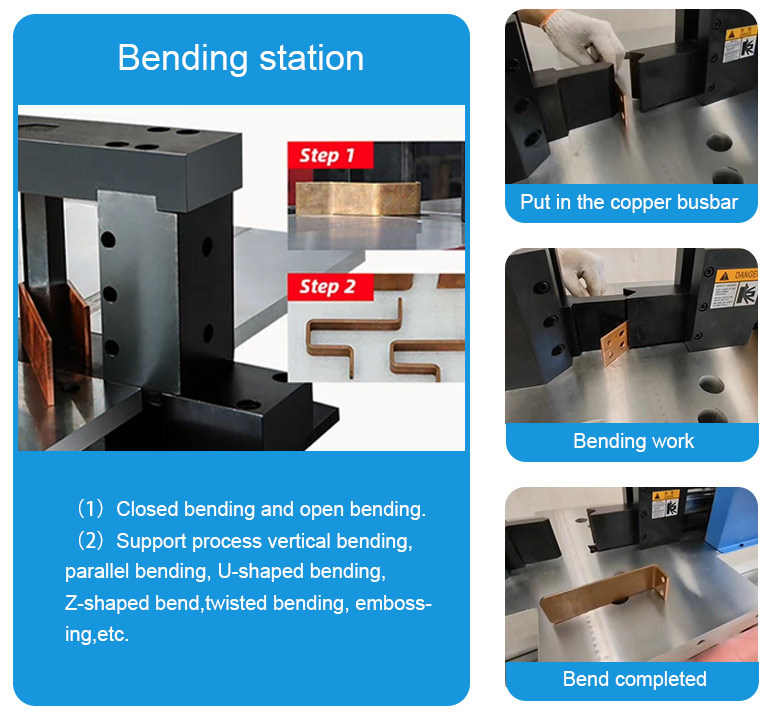

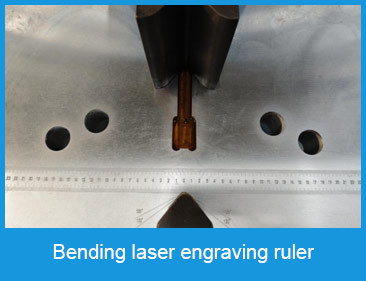

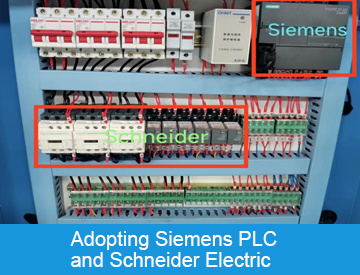

2.The graduation ruler of the bending station adopts laser engraving, which will not cause damage to the bottom of the copper busbar due to friction when working. | 3.Adopt Siemens PLC and Schneider Electric to ensure the safety and stability of the machine, avoiding machine fault and making it more durable. |

|  |

4.The punching and shearing stations are equipped with manual positioning rulers, which can accurately position the copper busbar without the need for marking during the work process, greatly improving work efficiency and processing accuracy. | 5.Equipped with automatic refueling function.Adopt three power motors are used, corresponding to the punching, shearing, and folding stations, to ensure stable power for the three stations, each performing its own duties without interfering with each other. |

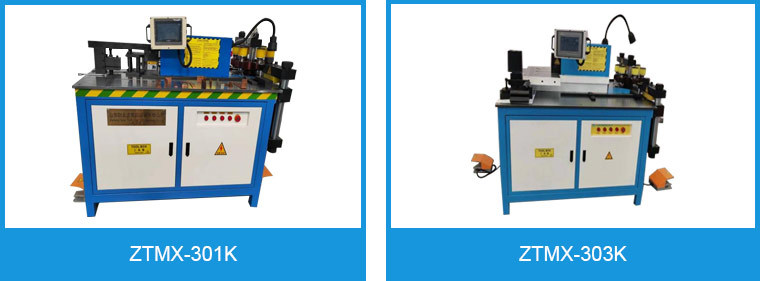

Different Products

(1)Motor:301K has one motor,punching, shearing, and bending can’t work at the same time;303 has three motors, and punching, shearing, and bending can work simultaneously.

(2)Efficiency: 301K is suitable for customers with smaller workloads. 303K has high efficiency and is more suitable for customers with larger workloads

Technical Parameter

Function | Item | ZTMX-301K | ZTMX-303K |

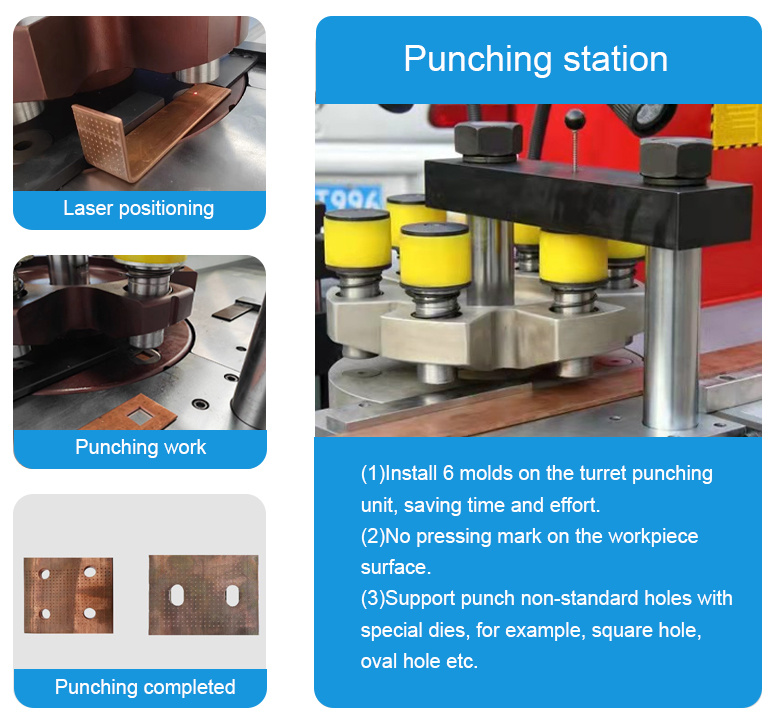

Punching

| Max power(KN) | 350 | 350 |

Punching Diameter (mm) | φ4.3-φ25 | φ4.3-φ25 | |

Max thickness (mm) | 15 | 15 | |

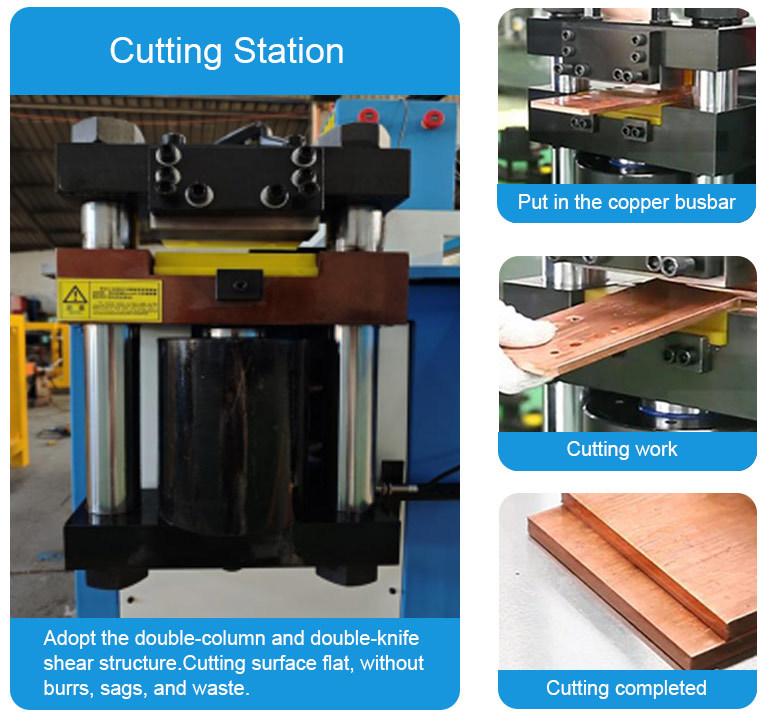

Shearing/cutting

| Max thickness (mm) | 15 | 15 |

Max width (mm) | 160 | 160 | |

Bending

| Max power (KN) | 350 | 350 |

Max width (mm) | 160 | 160 | |

Max thickness (mm) | 15 | 15 | |

Horizontal bending | Max size | 110*10 | 110*10 |

Power of Main Motor | (KW) | 4 | 3x4(12KW) |

Weight of machine | (T) | 1.3 | 1.5 |

Outline Dimensions | (mm) | 1800x1400x1300 | 1800x1400x1400 |

Size of worktable

| One floor | 1440mmX1240mm | 1440mmX1240mm |

Two floors |

| 890mmx500mm |

Support customization according to customer requirements.

Sample Display

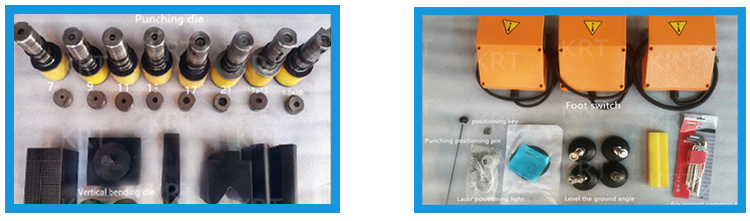

Product Accessories

No. | Item | Quantity | |

1

|

Punching die

| 8 sets

| Round hole:7/9/11/13/17/21 |

Oval hole:11×15/13×18 | |||

2 | Vertical bending die | 2 sets | (R5/R10) |

3 | Horizontal bending die | 1 set | |

4 | Die pins | 2 pieces | |

5 | Equipment manual | 1 set | |

6 | Foot switch | 3 pairs | |

7 | U-bending die | 1 piece | |

8 | Spare proximity switch | 1 piece | |

9 | Equipment common tool | 1 set | |

10 | Punching laser positioning light | 1 piece | |

11 | Punching positioning needle | 1 piece | |

12 | Embossing die | 1 set | |

13 | Spare sealing ring | 1 piece | |

14 | Level the ground angle | 4 pieces | |

| 15 | Cutting blade | 1 pc (Installed on machine) | |

| 16 | Small bending mold | 1 set(R3) | |

Packaging and Shipping

CNC BUSBAR MACHINE - ZTMX - 30 SERIES: Revolutionizing Busbar Processing

The ZTMX - 30 series of CNC busbar machines represents a significant leap forward in the field of busbar processing. These machines are engineered to meet the ever - increasing demands of modern electrical manufacturing industries.

1. Precision Engineering

The ZTMX - 30 series is renowned for its high - precision machining capabilities. With advanced CNC (Computer Numerical Control) technology, it can accurately shape and cut busbars with extremely tight tolerances. The machine’s motion control system ensures that every movement of the cutting tools and the positioning of the busbar are executed with micron - level accuracy. This precision is crucial for busbars, which play a vital role in electrical distribution systems, as it guarantees proper fit and connection in complex electrical assemblies.

2. Versatile Machining Functions

This series of machines offers a wide range of machining functions. It can perform various operations such as cutting, punching, bending, and notching on busbars. Whether it’s a straight cut for separating busbar segments, punching holes for mounting components, or creating precise bends to fit into specific electrical enclosures, the ZTMX - 30 series can handle it all. The ability to perform multiple functions in a single setup not only saves time but also reduces the potential for errors that can occur during part transfer between different machines.

3. High - Efficiency Production

In terms of production efficiency, the ZTMX - 30 series stands out. The CNC control allows for rapid programming and setup, enabling quick changeovers between different job requirements. Once the program is set, the machine can operate continuously at high speeds, significantly reducing the production cycle time. Additionally, the machine’s robust construction and reliable components ensure minimal downtime for maintenance, further enhancing its overall productivity.

4. User - Friendly Interface

The user - friendly interface of the ZTMX - 30 series makes it accessible to both experienced operators and those new to busbar processing. The CNC control panel features intuitive graphics and easy - to - understand menus. Operators can quickly input the required parameters for different machining operations, view the production progress, and make real - time adjustments if necessary. This ease of use helps to reduce the learning curve and enables operators to get the most out of the machine’s capabilities.

5. Quality and Durability

These machines are built to last. They are constructed using high - quality materials and components that are selected for their durability and resistance to wear and tear. The ZTMX - 30 series is designed to withstand the rigors of continuous operation in a busy manufacturing environment. This not only ensures a long - term investment for the users but also contributes to the consistent quality of the processed busbars over time.

6. Customization and Adaptability

The ZTMX - 30 series can be customized to meet specific customer requirements. Whether it’s adapting to different busbar sizes, materials, or unique machining processes, the machine can be configured accordingly. This adaptability makes it suitable for a wide variety of applications in different industries, from power generation and distribution to industrial automation and electrical equipment manufacturing.

In conclusion, the CNC BUSBAR MACHINE - ZTMX - 30 SERIES is a state - of - the - art solution for busbar processing. It combines precision, versatility, efficiency, user - friendliness, durability, and adaptability, making it an ideal choice for modern electrical manufacturing operations.

Our Factory

Why Choose Us?

1

We have our own factory.

2

Products can be customized

3

High quality product and good price.

4

Good Pre-sale、on sale and after sales service.

5

Short delivery time.

6

Exported all over the world, with rich experience.

Honor

RELATED PRODUCTS

MESSAGE